Description

GENERAL

The CKM model heater presents a cutting-edge solution as a seamless replacement for traditional convection-based systems. Engineered with a mechanically-driven pump and a custom-designed pump volute coupled with a stainless-steel tank, the CKM maintains compatibility in terms of dimensions and options with existing convection systems. Its versatile design allows for both vertical and horizontal installation, facilitating a swift and uncomplicated transition to an efficient forced circulation system. The CKM is meticulously crafted for an extended operational lifespan, providing accessibility to major operating components, and incorporating features such as a built-in air bleed screw and resettable high-limit thermostat.

In comparison, HOTflow® engine heaters revolutionize heating mechanisms by integrating a pump that uniformly circulates warm coolant throughout the entire engine. This constant circulation eradicates hotspots, preventing the degradation of heater hoses, safeguarding engine seals, and extending coolant life. The innovation behind HOTflow® engine heaters results in fewer heating cycles, leading to a remarkable 35% reduction in energy consumption. This not only extends the lifespan of the heater element but also reduces maintenance efforts.

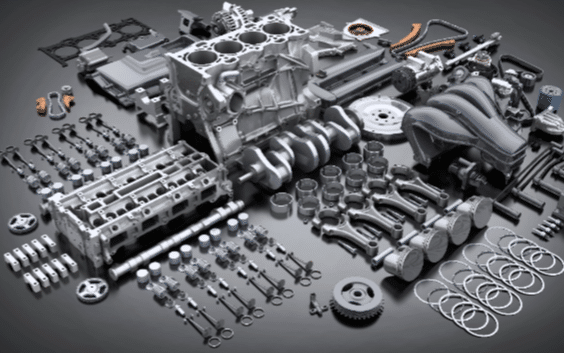

Crucially, preheating diesel or gas engines with these advanced heaters ensures a prompt and efficient start-up, minimizing wear on critical components. Industries heavily reliant on the consistent operation of engines, such as fleet vehicles, excavation, mining, data centers, and hospitals, benefit significantly from the advantages offered by reliable engine heating. This dependable heating solution maximizes equipment investment and eliminates downtime, catering to the specific needs of businesses where operational continuity is paramount.