Alternator overheating doesn’t happen by accident. It’s usually the result of overlooked load issues, poor airflow, or sizing decisions that don’t match real-world conditions. If left unchecked, the damage accumulates quickly and compromises both performance and lifespan.

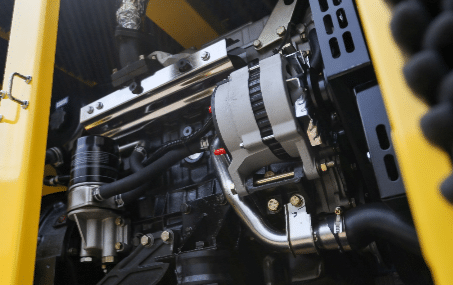

Mecc Alte alternators are designed to withstand demanding conditions, but even the best components can fail without proper support. Joval Industrial helps customers avoid that outcome by offering generator alternators that match your actual workload, not just the specs on paper. The right setup reduces wear, lowers risk, and keeps your power steady when it matters most.

Here are smart ways to avoid overheating and get more value out of your Mecc Alte alternators.

Key Takeaways

- Oversized alternators aren’t a waste of money when you’re trying to control heat and protect your system.

- Load stacking during startup pushes your alternator past safe limits faster than most people realize.

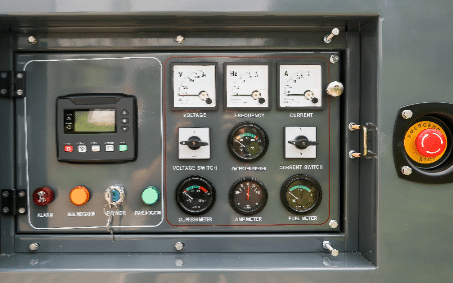

- Thermal sensors and real-time monitoring provide the opportunity to address issues before they cause damage.

Use Peak Load Buffers, Not Just Averages

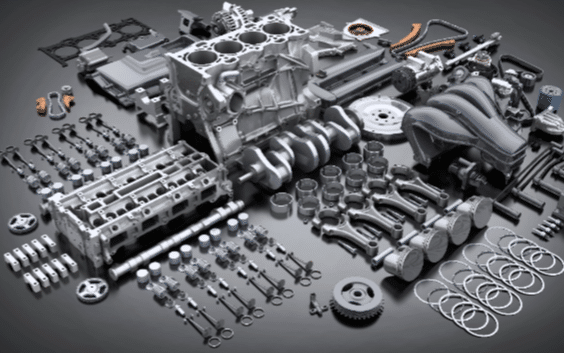

Average load data hides the truth about how your system behaves under stress. Short, sharp power surges create more heat than hours of normal use. If your alternator isn’t sized for those peaks, it runs hotter than intended and wears out faster.

Peak load buffers provide you with breathing room when demand spikes. Designing for the highest expected surge keeps your alternator cooler and more reliable. You spend less time on repairs and more time with stable power output.

Why Is My Generator Alternator Overheating

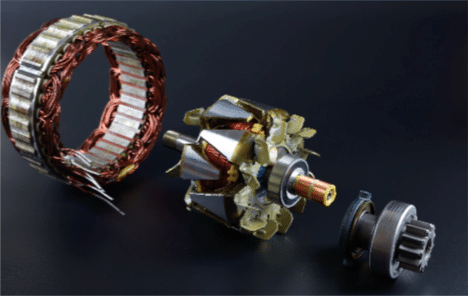

Your alternator overheats because it’s working harder than it was designed to handle. When power demand stays near maximum output, heat builds fast inside the windings. Constant strain on the system shortens its life and reduces overall performance.

Poor ventilation and blocked airflow are the primary causes of the problem. Dust, tight enclosures, or other heat sources nearby trap hot air, preventing proper cooling. Once the temperature rises above safe limits, insulation and bearings begin to deteriorate.

Need a long-term fix? Invest in reliable Mecc Alte alternators from Joval Industrial to keep your system running cool and consistent.

Stop the Cycle of Load Stacking

Load stacking occurs when multiple high-demand systems start simultaneously. Compressors, HVAC units, and motors draw heavy current simultaneously, forcing your alternator to overwork instantly. That kind of surge creates rapid heat buildup, which wears components down more quickly.

You can prevent this with a simple startup sequence. Staggering each system’s start time spreads out the power draw and keeps the alternator within safe limits. Minor timing adjustments protect your investment and keep power steady under pressure.

Small Fixes That Protect Your Mecc Alte Alternators

Overheating starts with small mistakes that are easy to miss. Joval Industrial helps you prevent those issues with generator alternators that match your real load demands. With the proper setup, your Mecc Alte alternators stay cool, steady, and ready for anything.

Frequently Asked Questions

How do I know if my alternator is too small for my generator setup?

If your alternator runs hot during normal operations or struggles during power surges, it’s likely undersized. Watch for signs such as frequent shutdowns, overheating, or loud startup noises.

What causes generator alternators to fail over time?

Constant operation near capacity, poor airflow, and unchecked load spikes all speed up wear. Over time, heat buildup damages internal components and reduces the alternator’s lifespan.

Can poor placement cause an alternator to overheat more quickly?

Yes, high ambient temperatures or tight enclosures can trap heat and reduce cooling efficiency. Placing your generator in a well-ventilated area or using thermal shielding helps avoid early failure.