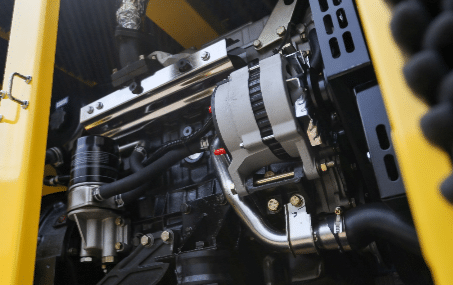

Matching industrial generator parts to the demands of your load isn’t just a technical step; it’s the foundation for a reliable power system. Every component plays a role in keeping operations running smoothly, and choosing the wrong one can lead to inefficiency or breakdowns. A thoughtful approach ensures your setup can handle everyday needs and unexpected spikes.

Joval Industrial has seen how the right combinations of parts can make all the difference in performance and lifespan. It’s not about buying the most expensive gear; it’s about making sure everything works together as a balanced system. That balance keeps power steady and downtime minimal.

Keep reading to learn practical tips for matching generator components to your specific load challenges.

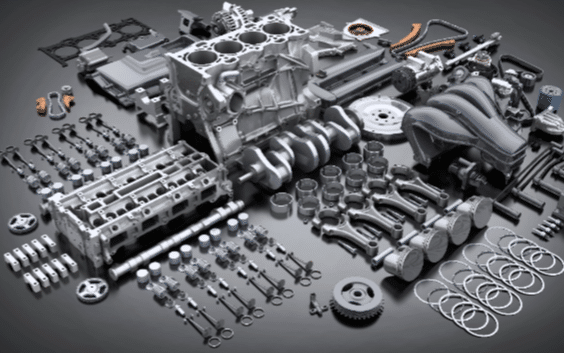

Start With an Accurate Load Profile

Before selecting components, track your electrical demand over a meaningful period. Capture variations across different operating conditions to avoid sizing mistakes that waste money or risk outages. The goal is to create a clear, data-backed picture of how your system behaves under every condition it will face.

Use that information to guide every component choice, starting with these focus areas:

- Peak Demand Analysis – Record your highest load events, including when multiple systems start at once. Use this data to size the generator to handle these spikes without straining or shutting down.

- Load Pattern Tracking—Monitor daily and weekly cycles to see how your load changes over time. This helps you choose components that operate efficiently during low demand while still meeting peak requirements.

- Seasonal and Environmental Factors – Track how temperature, humidity, and seasonal production shifts impact your load. These variables often cause fluctuations that can affect both generator capacity and component performance.

A complete and accurate load profile reduces the risk of system failures and ensures your investment performs as expected for the long term.

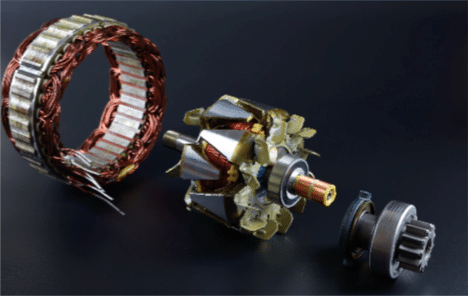

Match Alternator Capacity to Peak Demand

Alternators last longer when they run below their maximum output. Heavy loads for long periods create heat and wear that damage components. Extra capacity handles sudden power spikes without strain. This helps keep performance steady and reduces the risk of unexpected failures.

Accurate load measurements guide the right capacity choice. Peak usage data ensures the alternator stays efficient even during heavy demand. A slightly larger unit allows for future growth in power needs. This approach lowers wear and keeps the system dependable over time.

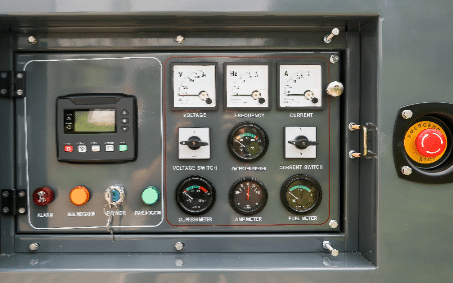

Configure the Transfer Switch for Your Load Type

A transfer switch must match the type of electrical system you use. Single-phase and three-phase systems require different pole configurations. Choosing the right amperage rating keeps the system safe during high demand. Incorrect sizing can cause overloads that damage equipment and stop operations.

Careful planning before installation prevents costly problems later. Match the switch capacity to both your average and peak load. Check manufacturer specifications to ensure compatibility with your generator and wiring. A properly configured transfer switch keeps power flowing smoothly during changeovers.

Getting the Most Out of Your Industrial Generator Parts

Matching the right industrial generator parts to your load needs isn’t complicated, but it does require attention to detail. Joval Industrial can help you choose components that work together for maximum reliability and efficiency. With the right setup, you’ll keep power flowing and problems to a minimum.

Key Takeaways

How do I determine the right generator size for my load?

Measure your electrical demand over time, including peak usage, startup surges, and seasonal changes. Use this data to choose a generator that can handle your highest load with a small capacity buffer for efficiency and reliability.

Why is alternator capacity important for generator performance?

An alternator with extra capacity handles power spikes without strain and avoids running at maximum output for long periods. This reduces wear, prevents overheating, and extends the life of your equipment.

What should I consider when choosing a transfer switch for my generator?

Match the transfer switch to your system type, whether single-phase or three-phase, and ensure it has the correct pole configuration and amperage rating. Proper sizing prevents dangerous overloads and keeps power flowing during changeovers.