Backup systems often fail because one small part doesn’t do its job. A generator transfer switch might seem minor compared to the generator itself, but it’s the link that decides if power keeps flowing or cuts out. When the switch struggles under pressure, the entire backup plan collapses.

Weak components, poor configurations, or a lack of testing all create cracks in reliability. Add in environmental stress or outdated firmware, and you have a recipe for sudden downtime. These failures rarely show themselves until the moment you need the system most.

Joval Industrial offers transfer switches built to handle real-world conditions without faltering. Strong construction, accurate ratings, and smart controls mean your operation stays protected.

Below are some ways bad transfer switches turn outages into disasters.

Underrated Amperage Turns Into a Silent Overload

A switch rated below the actual demand seems fine until the system experiences heavy use. Extra current flows through smaller components, heating them up gradually. That heat wears parts down until, one day, the switch gives out without warning.

Hidden overloads often escape notice during routine checks. Stress builds when the load spikes, and the system has no margin for error. Operations stop suddenly, leaving teams scrambling to restore power.

Poor Pole Configuration Scrambles Power Flow

A mismatch between single-phase and three-phase systems puts your power flow at risk. The wrong pole setup confuses current paths and throws the load off balance. That imbalance pushes breakers to trip and brings equipment to a halt.

Miswired poles create gaps where power fails to reach critical systems. The strain often spreads across connected racks, causing wide outages. Operations stall while teams track down a problem rooted in a simple configuration error.

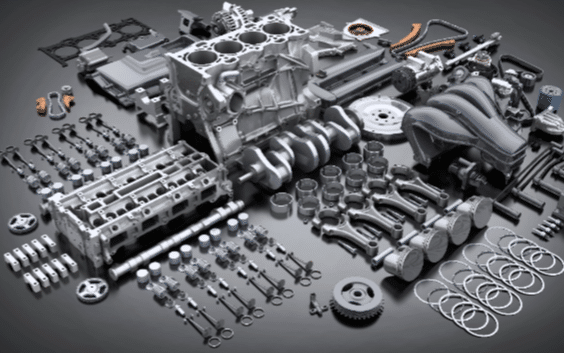

Cheap Components Break Under Real-World Stress

Low-grade contacts and thin enclosures look fine in testing but fail when conditions get rough. Heat softens weak metals, dust interferes with connections, and vibration shakes parts loose. Those minor flaws build into outages that stop critical systems.

Stress from daily operations reveals shortcuts in design that would never pass in the field. Cracked housings or burned contacts force sudden shutdowns and costly repairs. Strong materials and solid construction prevent these failures before they spread.

Protect Uptime with the Right Generator Transfer Switch

Bad switches turn backup plans into downtime, but the right equipment keeps power steady when it matters most. Joval Industrial provides durable transfer switches built to meet the demands of real operations. Choosing the right switch today prevents costly outages tomorrow.

Key Takeaways

What happens when a transfer switch has the wrong amperage rating?

An underrated switch overheats as current demand rises and parts wear down until the system fails. These hidden overloads often stay unnoticed until a heavy load forces a sudden outage.

How does poor pole configuration affect backup power?

Using the wrong setup for single-phase or three-phase systems scrambles current paths and unbalances the load. Breakers trip, racks shut down, and operations stall until the error is corrected.

Why do cheap transfer switch components fail in the field?

During real use, weak contacts and thin enclosures cannot handle heat, dust, or vibration. These stresses crack housings or burn contacts, leading to shutdowns and expensive repairs.