Standby generators are commonly installed as safety precautions that are ready to go in the event of an outage or natural disaster. This gives business owners peace of mind that they’ll be able to operate and avoid monetary losses which could be detrimental to their bottom line. Most business owners perform routine inspections and maintenance on their building and/or equipment to ensure everything is in good working order. Unfortunately, one of the items most often overlooked during these inspections is the generator. A lack of scheduled preventative maintenance happens to be the greatest cause of generator failure.

Preventative Maintenance

A regular maintenance plan for your generator is the most reliable way to ensure it’s in good working order when you need it most. Routine maintenance helps prolong the life of your generator to ensure your business is up and running even during a power failure. While some may see this as an unnecessary cost, it’s actually a small investment that helps minimize repairs for your generator. A well-maintained generator runs better longer and costs less to operate.

Recommended Service

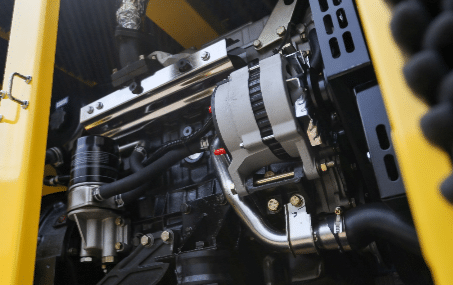

It is generally recommended you service your generator twice annually. Some models may require more maintenance depending on the age of the machine and how often it is used. For lightly used generators, most manufacturers recommend starting and running the machine for at least 30 minutes every three to four months. You’ll also want to inspect all the belts, cables, and connections very closely while looking for any signs of physical damage on the outer machine.

Trained Technicians

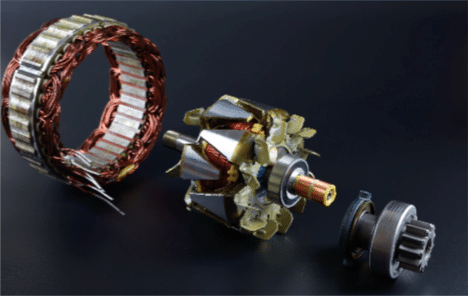

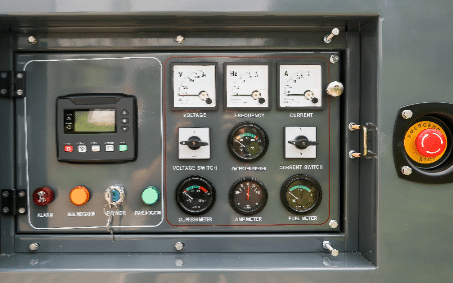

You can perform regular preventative maintenance on your generator or hire a trained professional who will inspect the unit closely during maintenance check-ups. He will test things like the voltage regulator and governor control to ensure optimum performance output. The fuel system will be checked for leaks and the actuator should be examined among other things. Symptoms of generator failure are not always immediately apparent. Identifying issues early allows you to correct them before they get bigger and more expensive.

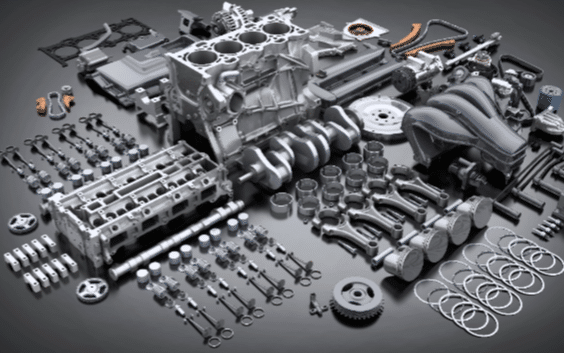

Avoiding Failure

Some of the most common causes of generator failure include normal wear and tear, overheating due to a lack of coolant, bad fuel, and burnt electrical components. Many of these issues can be avoided altogether with routine maintenance. It’s also imperative that you choose the right cord for your generator. Heavy-duty cords work best because they conduct less voltage to prevent premature engine burn-out. When it’s time to replace parts on your generator or conduct performance maintenance, Joval Industrial is a one-stop shop for all your power generation equipment needs.