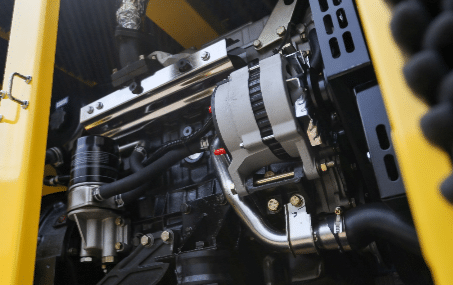

Power generation is an intricate process that involves various components working seamlessly together. One crucial part of this assembly is the generator end, often described as the heart of power generation. It is a vital component responsible for converting mechanical energy into electrical energy.

Without a properly functioning generator end, the entire power generation system would be rendered useless. This is why understanding the inner workings of generator ends and how to maintain them is crucial.

Keep reading to learn more about generator ends and their vital role in power generation.

Understanding Generator Ends

Generator ends, also known as alternators, are vital in power generation. Imagine a generator as a big machine. In that machine, the generator end is like the heart.

It has an important job: it takes the energy produced by the generator’s engine — which is mechanical energy, like the kind you use to ride a bike or lift a heavy object — and changes it into electrical energy.

This electricity powers things like your lights, computer, or refrigerator. Without the generator end doing its job, it wouldn’t be able to produce the electricity we need daily.

Components of Generator Ends

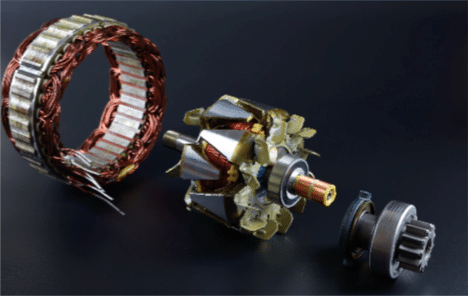

Generator ends function effectively due to the interaction of several key components. These parts work together to convert mechanical energy into electrical energy. Below are the primary parts of a generator end:

- Stator: This is the stationary part of the generator end. It’s made up of tightly wound wires that create a magnetic field when electricity flows through them.

- Rotor: This is the part that spins within the stator. As it spins, it creates a changing magnetic field that generates electrical energy.

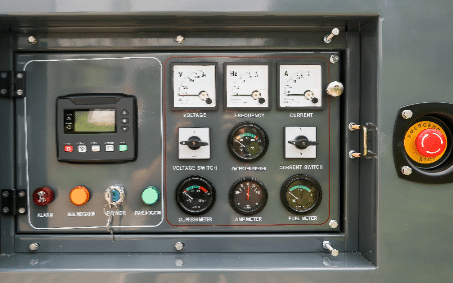

- Voltage Regulator: This part controls the electricity produced by the generator end. It ensures the power output remains steady, regardless of how fast the rotor spins.

- Bearing: This part helps the rotor spin smoothly within the stator. It reduces friction, which can wear down the generator end over time.

Understanding these components will help in the routine maintenance of your generator end, ensuring it functions optimally and extends its lifespan.

Types of Generator Ends

Different types of generator ends are available, each designed for specific applications and power setups. Let’s look at the main types.

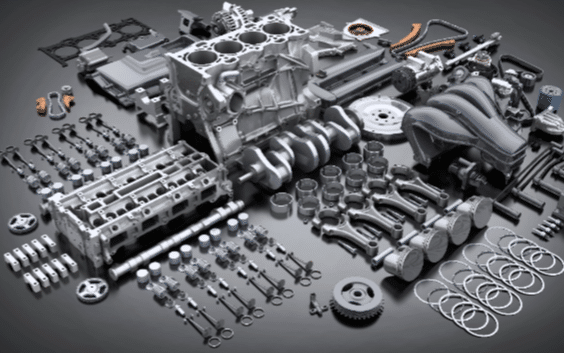

Single Bearing Generator Ends

This type is directly connected to the engine. Imagine a bicycle where the pedals are directly linked to the wheels. When the engine runs, the single bearing generator end turns and produces electricity.

Double Bearing Generator Ends

These are a bit different. They have two bearings that help to balance the load and ensure smooth operation. It’s like having two strong people carry a heavy table instead of one. This improves the longevity and performance of the generator end.

Belt-Driven Generator Ends

These are typically used in smaller setups. A belt-driven generator end is like a bicycle with a chain. The engine turns a belt, which then turns the generator end. This type allows for flexibility in positioning the generator end with the engine.

Understanding the types of generator ends helps when choosing the right one for your power needs.

We Have High-Quality Generator Ends in Stock!

Are your existing generator ends worn out and unreliable? If so, check out the selection of affordable generator end replacements we have in stock!