It doesn’t matter if you use your industrial generator as a main or backup power source; they are important in your operations. Generators have the job of supplying power to your job site, facility, or building.

To ensure your generator can operate properly and efficiently when needed, it is paramount that you invest in regular maintenance.

Top Benefits of Regular Industrial Generator Maintenance

When you maintain your industrial generator regularly or hire someone to do this for you, there are several benefits:

- Identify possible issues before they turn into expensive problems

- Monitor the condition of the important parts to determine if there are signs of wear and tear

- Allow your power generator to run more efficiently

- Achieve a higher level of control over your repair and operating costs

While it is possible to perform some industrial generator maintenance yourself, other parts of this are more complex and should be left to the pros.

DIY Industrial Generator Maintenance Tips

You can follow these steps to ensure your equipment continues operating efficiently and to detect any possible signs of a problem.

Daily Maintenance Tasks

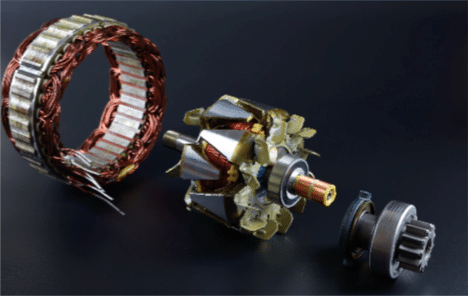

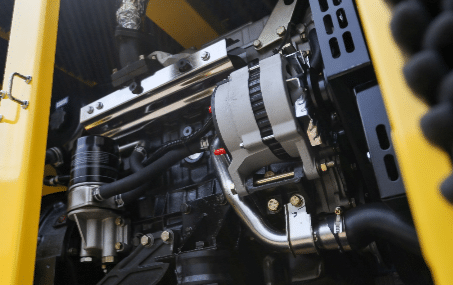

Every day you should visually inspect your generator—some of the items you need to check to include the coolant and oil levels. You also need to look at the transfer switch, alternator, and water pump belt condition. Make sure to look under the generator to see if there are any signs of a leak.

Weekly Maintenance Tasks

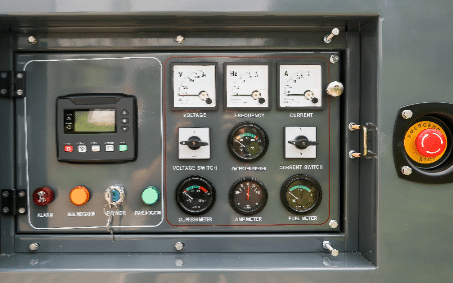

One time a week, it’s a good idea to run your generator on the no-load setting. This will assure you that it will operate without any warning signals or alarms. After that, inspect the battery charger to ensure there are no faulty connections or loose wires.

Professional Industrial Generator Maintenance Tips’

While inspecting your industrial generator yourself is a smart move, it’s still important to have a professional inspect the equipment from time to time. This is especially important as it gets older.

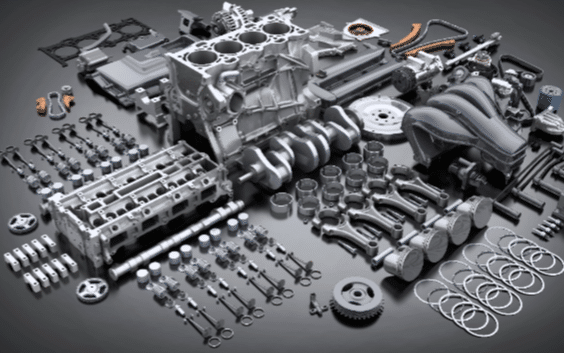

The scope and nature of the service needed depend on factors like the make, model, age, and frequency of unit use. However, when you call in the professionals for an inspection, they will focus on the engine, exhaust system, electrical system, control system, and fuel system.

With a professional inspection, it is possible to find issues and prevent all types of issues, including:

- Malfunctions with the pump system that result in the generator running out of fuel.

- Block heater wear and tear that prevents the proper heating of the generator’s coolant.

- Signs of battery failure (the average industrial generator battery will last for about four years).

- Fuel that is leaking into the tank.

Don’t Ignore the Importance of Industrial Generator Maintenance

You can’t afford to ignore the importance of industrial generator maintenance. Regular maintenance can help ensure the system is working efficiently and that no issues require repairs or service. Without regular inspections, you may experience a complete failure of your generator, which can cost you time and money.