Generators deliver the power needed for equipment to run smoothly, effectively, and efficiently in industrial settings. When industrial generators experience problems or fail to provide power altogether, the repercussions can be devastating. If you know the most common causes of generator failure, you head off trouble at the pass and prevent unnecessary downtime.

Neglected Maintenance

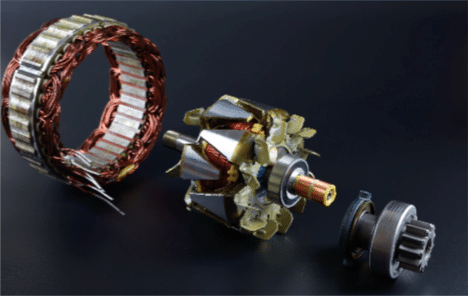

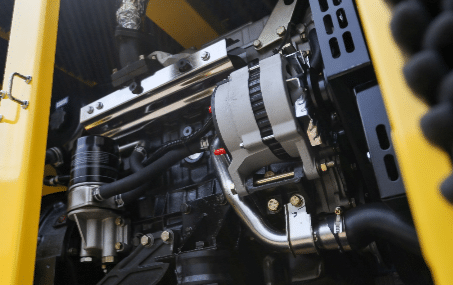

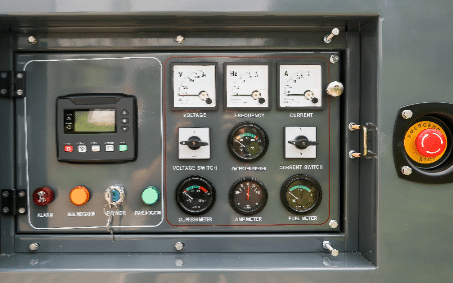

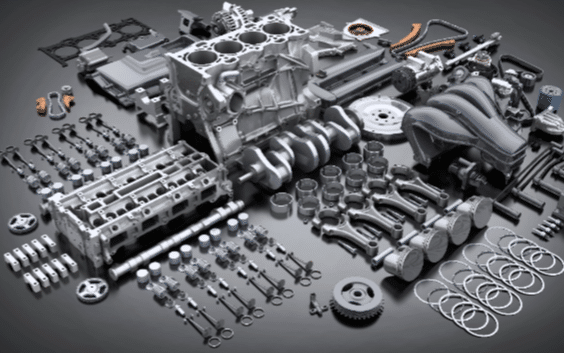

Perhaps the most common and preventable problem of a failing generator is neglected maintenance. Industrial generators have many internal components that must stay in top condition and free from wear and tear to work correctly. Preventative maintenance is vital to the health of a generator and thus, should be scheduled per the manufacturer and distributor’s recommendations.

Typically, industrial generators should receive a semi-annual or annual service and inspection that checks for signs of potential problems. Some of the main generator components, such as its cooling system, air induction and exhaust, fuel system, engine motors, and control panels, are only a few that should be assessed in routine maintenance. Diesel generators should also undergo annual load bank testing, eliminating wet stacking by burning off unburnt fuel, carbon, and oil in the exhaust system and cylinders.

Improper Generator Load And Sizing

Sometimes, industrial generators fail due to being improperly sized. When generators are not the correct size for the job and thus are improperly loaded, it can result in severe damages and wasteful inefficiencies. Industrial generators must utilize at least 35% of their load capabilities to remain running efficiently. While you may initially feel that installing a more significant generator than you need now, it is better to increase generator size if required for the future rather than install one too big.

Improper load and sizing can result in the generator’s engine’s operating temperature not rising enough for the expansion joints in the exhaust system to seal correctly. Running a light load doesn’t allow the diesel fuel to completely burn off, resulting in wet conditions in the engine stack or wet stacking.

Not Enough Fuel Supply

When industrial generators do not have enough fuel supply, they shut down for lack of power. Also, lacking fuel supply can lead to low airflow into the generator’s fuel system, which can cause it to shut down. If the generator receives too little fuel, contamination and sludge can create clogs, cause leaks, and damage fuel filters over time. Make sure your operators supply the correct fuel levelof for your industrial generator to run smoothly and without damage.