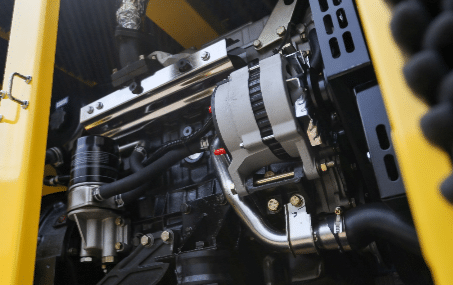

Emergency generators are lifesavers for all types of businesses and industries. Having backup power in an outage, or other emergency, is essential to maintaining operations. Many companies fail to maintain their emergency generators properly, unaware of problems until something goes wrong when backup power is needed. If your company purchases an emergency generator, it is wise to understand the basics of maintaining and servicing the machine.

Below are key points to keep in mind about troubleshooting and repairing emergency generators.

Safety First

Any type of powerful industrial machinery should be handled with care. When dealing with a generator, your first concern should always be safety. Before you work on an emergency generator, inspect it thoroughly to ensure the area has proper ventilation and no structural damage. Inspect your surroundings for water, and wear protective clothing like gloves and safety glasses before checking the generator’s oil, filters, electrical system, and other parts. Before you begin troubleshooting, clear the area of other people or employees.

Refer To The Manual

Before troubleshooting your emergency generator, it is essential to understand its components and functions. Your generator’s manual holds valuable information about your specific machine. Once you have referred to the manual and familiarized yourself with it, you cannot deviate from the manufacturer’s instructions for troubleshooting. This could cause further damage or nullify a warranty.

Repair And Diagnostic Skills

If you are a technician who performs generator repair, you should be able to diagnose and correct electrical and mechanical problems promptly. But if you are not familiar with emergency generator troubleshooting, here are common issues to look for:

- Inspect the air and fuel filters to ensure they are clean.

- Make sure remote monitoring is working.

- Check to see if the cooling system is preventing overheating.

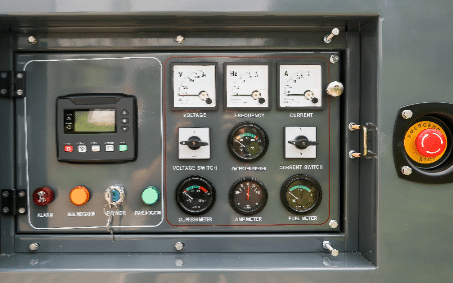

- Check to see if the utility power is correct.

- Check the automatic voltage regulator for frequency and voltage.

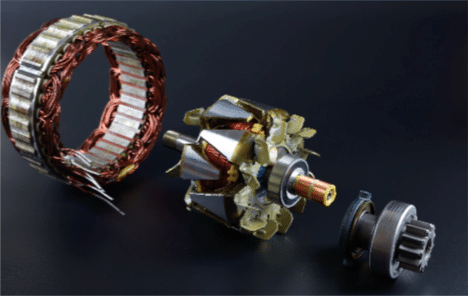

- Check the battery, fuses, relay, stator, or rotor (if they need replacing).

If you lack the technical expertise to perform root-cause diagnostics on your generator, it could lead to expensive and undue repairs. Emergency generator repair is complex and requires specific training along with hands-on experience to be done correctly. However, knowing the areas of the generator to check if problems arise will help you troubleshoot before calling a generator repair service.

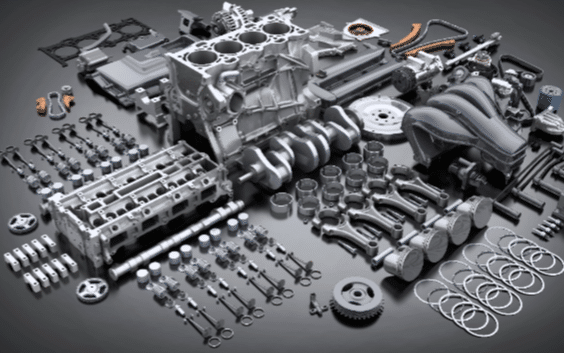

High-Quality After-Market Replacement Generator Parts

Emergency generators repaired with high-quality, after-market generator replacement parts can keep your business powered in an outage or other situation. You must know how to troubleshoot primary areas and problems that affect generators to help you make the best decisions for your company. The first rule of thumb is to always put safety first. If you ever feel the area around the generator is unstable or are not confident in your troubleshooting skills, call a professional generator repair technician to tackle the job.