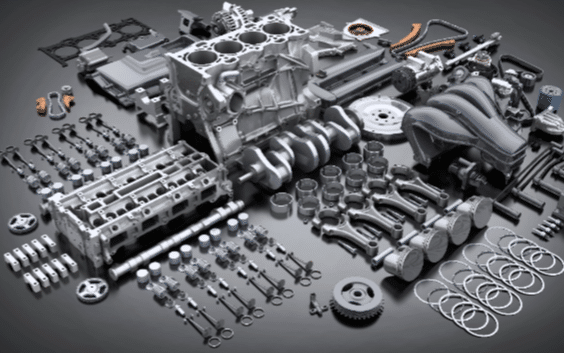

Like cars and trucks, commercial generators have engines and electronics that require regular maintenance to work efficiently. Regardless of how often your commercial generator is used, performing maintenance will ensure it has a long life with minimal downtime. Maintenance schedules also offer cost-saving opportunities to complete minor repairs and parts replacements, keeping you from having to purchase a new generator before necessary.

How Often To Service Your Commercial Generator

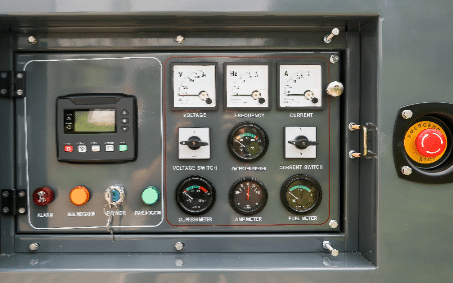

If you have a standby generator that runs less than 50 hours each year, it is sufficient to perform a preventative maintenance level 2 (PM2) annually. A PM2 is an overall inspection of the condition of the generator, including:

- Replacing engine oil and oil filters

- Replacing the fuel filter on diesel engines

- Sampling oil, coolant, and diesel fuel as needed

If any concerns are noted during the PM2, or you begin to experience issues with your generator, a semi-annual inspection should be conducted (every six months). Maintenance and repairs can be performed during examinations, and recommendations are made for any follow-up as noted.

Load Bank Testing

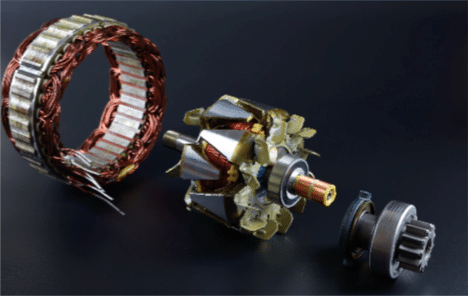

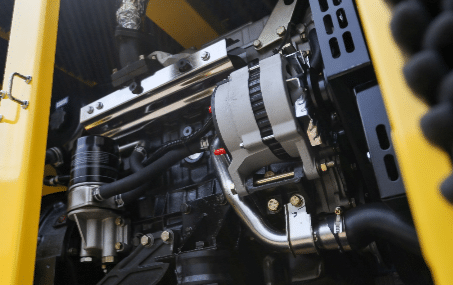

Some industries and facilities are required by law or code to perform load bank testing on commercial generators annually. The load bank applies an electrical load to the generator end, which applies a mechanical load to the diesel or natural gas engine. In a load bank test, the engine and generator (alternator) are operated at heavy loads to increase exhaust temperatures and verify the operation of:

- Engine cooling system

- Automatic voltage regulator and excitation system

- Fuel system

The load bank test also helps to eliminate wet stacking in diesel engines. Generator manufacturers have standards for maintenance recommendations that should be used as guidelines for load banking tests and other maintenance inspections.

Benefits To Commercial Generator Maintenance

Industrial generators can last a long time if properly maintained. Replacing parts on a generator is far less expensive than purchasing a new industrial generator. A little maintenance on the generator can go a long way to ensure your commercial facilities remain in working order. Generator maintenance and repair keep you up and running, and protect your bottom line.

If your generator shows wear and tear, it is in your best interest to have it serviced to ensure it is in optimal condition. Continued upkeep of your generator is necessary, even if it is only used as a backup power source. Maintenance is the way to go because you don’t want to find out that your generator needs repair at the moment when you most need it.